Zimmer® has over 25 years of experience recycling polyamide materials, where solid waste is converted back to high purity monomer that exceeds typical raw feedstock!

This technology builds upon our patented Flexi-Recovery® technology providing a cost-effective solution whilst reducing the overall carbon footprint of the final polyamide products.

Polyamide 6 is the preferred material in many applications, e.g. Automotive, packaging, infrastructure, textile & fishing gear industries due to its elasticity, high tensile strength, high abrasion resistance & high chemical resistance. However, these same properties also impede biodegradation leading to persistence and accumulation in landfills and the environment. Consequently, with higher raw materials costs and more environmental regulations there is a strong and growing driver to reuse, repurpose and recycle polyamide waste.

Mechanical recycling is a cost effective but rarely used solution for polyamides because elevated temperatures and mechanical stretching lead to partial degradation of polyamide chains and the production of lower value products with inferior properties. Incineration for energy recovery is also problematic due to the creation of toxic gases, release of captured CO2 into the atmosphere and loss of valuable caprolactam.

For successful chemical recycling, the source and composition are well known e.g. Fishnets/production waste.

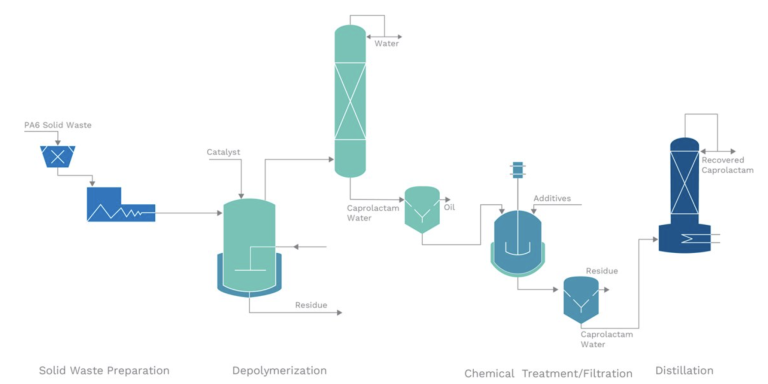

First, the polyamide 6 must be separated from other polymers, ground into pellets and washed to remove contaminates. The polyamide 6 is then depolymerised back to caprolactam, purified and recovered for production of new polyamide 6 products. Significant cost and process efficiencies can be achieved when solid recovery is combined with waste recovery from a polyamide 6 production facility.

Contact Our Experts

Thomas Brauburger

Director Sales

Dr. Marius Hackel

Head of Product Management and R&D

Tel: +49 (0) 69 667784 500